MOUNTAIN BUFFALO PRODUCTS

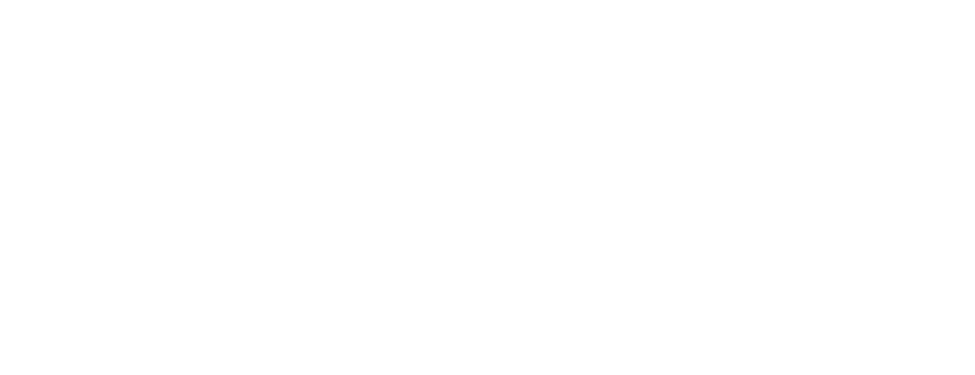

LOCK-HORNS LH21 COUPLING

Tight Joint Design reduces leading edge erosion

Enhanced Ring Ovality

Improved Seal Design doubles effective sealing surfaces

Improved Ring Design eliminates pinched gaskets

Wider and Stronger to improve operating integrity

Ease of Fit-Up

Common Bolting Systems

Rigid & Flexible Connection Options

North American Forging, Casting, & Manufacturing

*Image not to scale. For visualization purposes only.

Tight Joint Design reduces leading edge erosion

Enhanced Ring Ovality

Improved Seal Design doubles effective sealing surfaces

Improved Ring Design eliminates pinched gaskets

Wider and Stronger to improve operating integrity

Ease of Fit-Up

Common Bolting Systems

Rigid & Flexible Connection Options

North American Forging, Casting, & Manufacturing

*Image not to scale. For visualization purposes only.

Cost Saving

Advantages

Cost Saving

Advantages

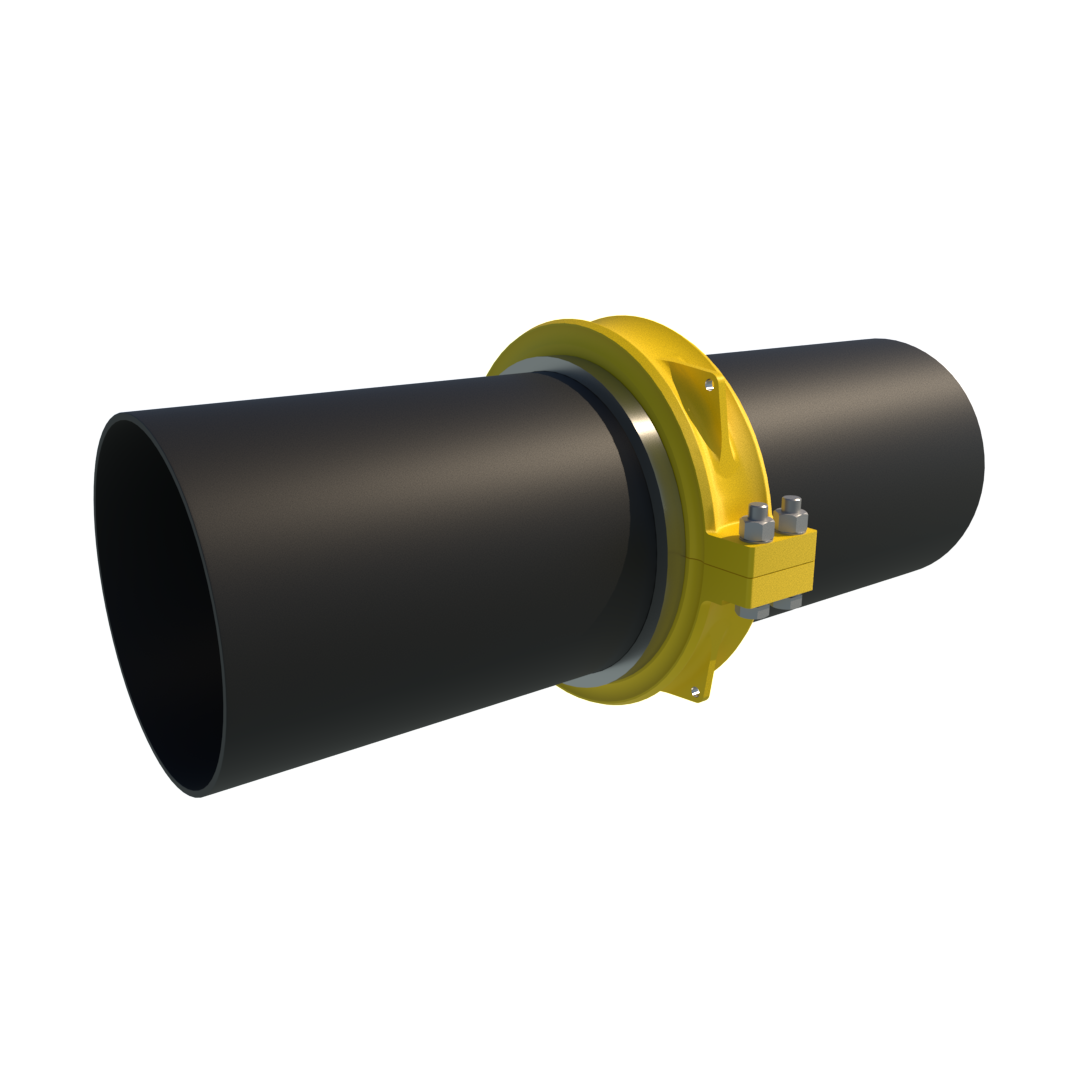

IRON GRIP IG21 HDPE COUPLING

No Pinched Gaskets, Decreasing rework

Mechanical Sealing

Integrated lifting lugs

Installs Faster and Safer

Enhanced Ring Ovality

Ease of Fit-Up

Lighter and Stronger

Three integrated Sealing Surfaces

Common Bolting Systems

North American Forging, Casting, & Manufacturing

*Image not to scale. For visualization purposes only.

No Pinched Gaskets, Decreasing rework

Mechanical Sealing

Integrated lifting lugs

Installs Faster and Safer

Enhanced Ring Ovality

Ease of Fit-Up

Lighter and Stronger

Three integrated Sealing Surfaces

Common Bolting Systems

North American Forging, Casting, & Manufacturing

*Image not to scale. For visualization purposes only.

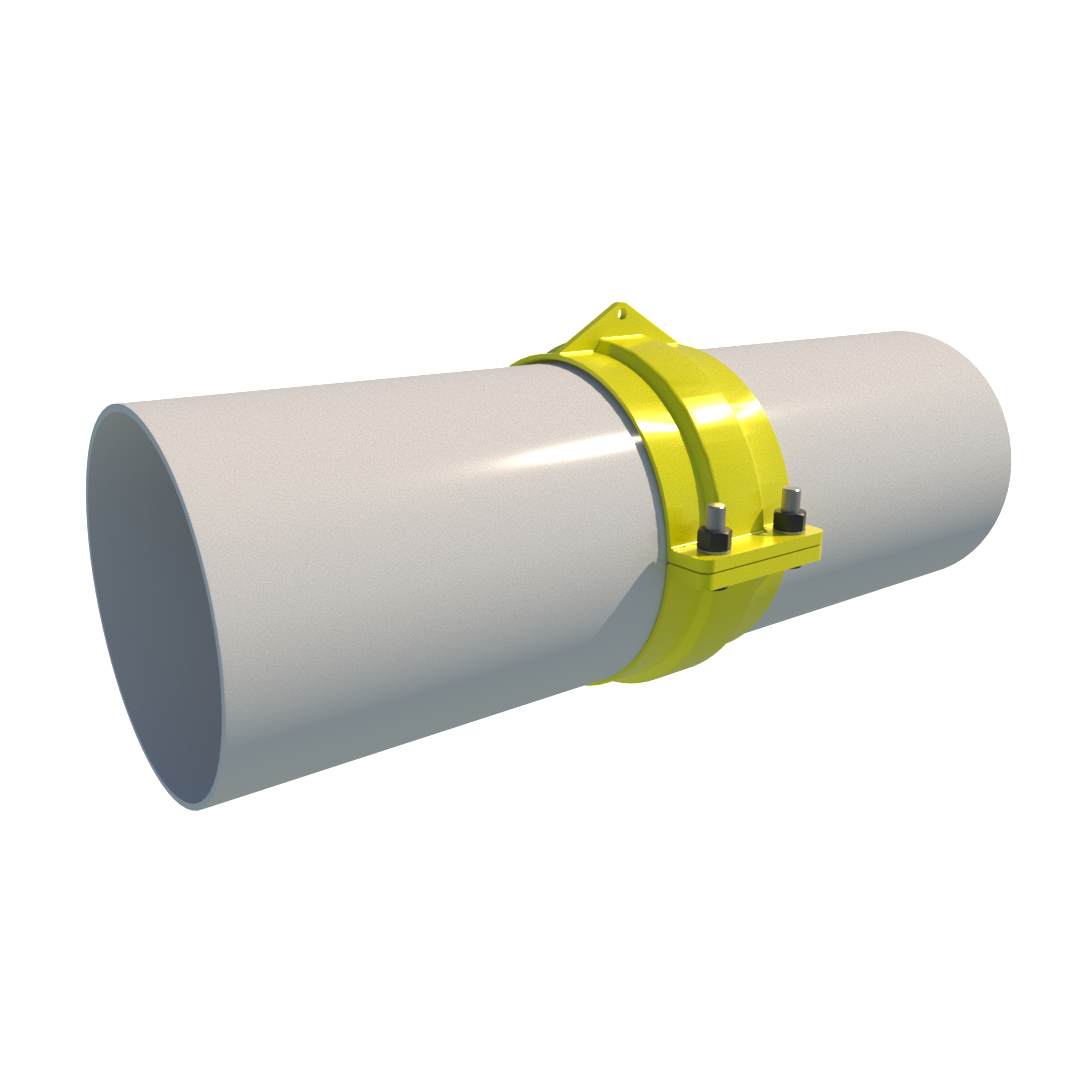

SANASK* VULCANIZED RUBBER-LINED PIPE INSERT

*Sanaskipicikew S/he pulls together securely.

Source: Alberta Elders' Cree Dictionary, Earle Waugh

No Need for Bolted Joints

Insert design improves vulcanized bonding strength

Exceeds 50 lb ASTM Rubber Pull

Improved Pipe Connection Integrity Test

Safe, Corrosion-Resistant Seal

Perfect for Pipelines Sensitive to Joint Leaks or Buried Applications

Significantly Less Maintenance Required

*Image not to scale. For visualization purposes only.

No Need for Bolted Joints

Insert design improves vulcanized bonding strength

Exceeds 50 lb ASTM Rubber Pull

Improved Pipe Connection Integrity Test

Safe, Corrosion-Resistant Seal

Perfect for Pipelines Sensitive to Joint Leaks or Buried Applications

Significantly Less Maintenance Required

*Image not to scale. For visualization purposes only.

CRIMPING

Fast process able to provide temporary connections for distribution applications

Uses currently available pipe up to 48" in diameter

Able to nest wall thicknesses up to 2"

*Image not to scale. For visualization purposes only.

Fast process able to provide temporary connections for distribution applications

Uses currently available pipe up to 48" in diameter

Able to nest wall thicknesses up to 2"

*Image not to scale. For visualization purposes only.

INSTALLATION SUPPORT

We install our products on pipe to provide system solutions

Long term relationships with engineering and constructors allows us to offer comprehensive end to end piping solutions for tailings applications

Installation of pipe coupling rings

Complete crimping services

We also offer Ring Welding and Insert Welding services

We install our products on pipe to provide system solutions

Long term relationships with engineering and constructors allows us to offer comprehensive end to end piping solutions for tailings applications

Installation of pipe coupling rings

Complete crimping services

We also offer Ring Welding and Insert Welding services